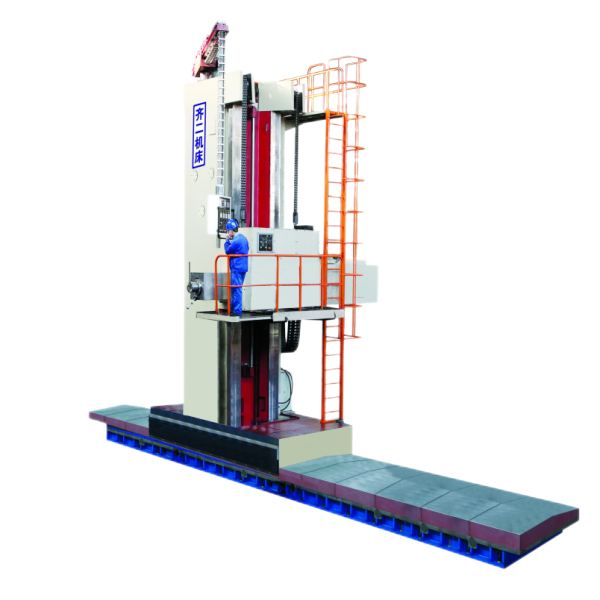

Reasonable selection of CNC machine tools is an inevitable trend in the future

CNC machine tool is a flexible and efficient CNC machine tool. It is equipped with a program control system, which can well solve the complex, precise, small batch, and multi-variety parts processing. CNC technology is an important symbol to measure the degree of modernization of a country's manufacturing industry. It is an inevitable trend for the development of today's manufacturing industry to realize the numerical control of CNC machining machines and their production processes.

According to the processing technology of CNC machine tools, it can be divided into traditional CNC machine tools such as turning, milling, drilling, grinding, gear, etc; CNC lathe, CNC milling machine, drilling machine, grinding machine, gear processing machine, etc. The rational selection of CNC machine tools should follow the following principles:

1. Preliminary preparation:

To determine the process requirements of typical parts, the batch size of processed parts, and the functions that the CNC lathe should have are to do a good job of preliminary preparation. The prerequisite for reasonable selection of the CNC lathe is to meet the process requirements of typical parts. The process requirements of typical parts mainly include structural dimensions, processing range, accuracy requirements, etc. The control accuracy of CNC lathe is selected according to the requirements of accuracy, dimensional accuracy, positioning accuracy and surface roughness. Reliability is an important guarantee for improving product quality and production efficiency. The reliability of CNC machine tool means that the machine tool can work normally under specified conditions and work stably for a long time without failure. That is, the average service time is long, even if there is a failure, it can be restored in a short time. Select machine tools with reasonable structure, excellent manufacturing and mass production. In general, the reliability of the CNC system increases with the increase of the number of users.

2. Purchase machine tool accessories and tools:

Machine tool random parts, spare parts, spare parts supply capacity, tools, etc. are of great significance to CNC lathes and turning centers that have been put into production. When selecting the machine tool, carefully consider the matching of tools and accessories.

3. Focus on the identity of the control system:

Manufacturers generally choose products from the same manufacturer, and at least buy control systems from the same manufacturer, which can greatly facilitate maintenance work. In teaching units, due to the high requirements for students' knowledge, it is a wise choice to choose different systems and provide various simulation software.

4. Select performance-price ratio: functions, precision, waste, and functions unrelated to their own needs.

5. Machine tool protection: if necessary, the machine tool can be equipped with fully closed or semi-closed protection device and automatic chip removal device.