Features of CNC milling machine

CNC milling machine can accurately calculate the working time of parts, effectively simplify the management of inspection tools and semi-finished products, and is conducive to the modernization of production management. The digital information used by the gantry milling machine is suitable for computer networking and becomes the basis of computer-aided design, manufacturing and management. The time required for processing parts includes two parts, namely, mobile time and auxiliary time. Gantry milling machine can effectively reduce these two parts of time, thus improving processing efficiency.

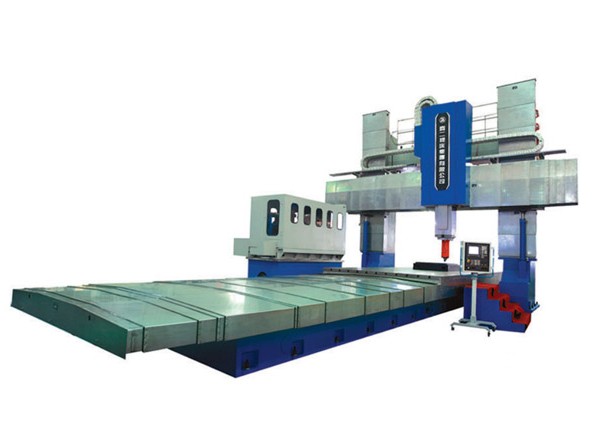

The range of spindle speed and feed speed of CNC milling machine is much larger than that of ordinary machine tools. Therefore, favorable cutting parameters can be adopted in each process and step feed to give full play to the potential of the process system. The gantry milling machine has a good structure rigidity, which allows a large number of powerful cutting, and effectively saves the mobile time. The moving parts of the gantry milling machine move fast in the empty stroke, and spend much less time on auxiliary motions such as feed, withdrawal and positioning than ordinary machine tools.

In mass production, the gantry CNC milling machine hardly needs to readjust the machine tool when replacing the processed parts, so the installation time is short. Running the milling machine according to the coordinates can save auxiliary processes such as marking and reduce auxiliary working hours. The machining accuracy of the gantry milling machine is relatively stable. Generally, only the first article inspection or the sampling inspection of key dimensions between processes can reduce the downtime inspection time. Therefore, the utilization rate of gantry milling machine is much higher than that of ordinary machine tools. On the compound machining center with automatic tool change, multi-axis and automatic feeding device, it can realize multi-process continuous processing, shorten the logistics process, reduce the turnover time of semi-finished products, and gradually improve the production efficiency.

CNC milling machine processes according to the instructions given in digital form. At present, the pulse equivalent given by the numerical control device (each output pulse corresponds to the movement of the moving parts of the numerical control milling machine) generally reaches 0.001 mm, and the reverse clearance and pitch error of the feed drive chain can be compensated by the numerical control device. Therefore, CNC milling machines can achieve relatively high accuracy, such as 0.002~0.001 positioning accuracy.