Vertical Turning And Milling Machining Center

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. Due to the simple structure of the Vertical turning and milling machining center, it is very easy to clamp the workpiece. Common fixtures, such as flat jaws, pressure plates, indexing heads, and rotary tables, can be used to clamp workpieces. The clamping positioning and repeated positioning operations are very convenient and simple.

2. The structural design of the Vertical turning and milling machining center is conducive to cooling, because the coolant is sprayed from top to bottom and can be directly sprayed onto the high-temperature workpiece and tools during machining.

Introduction of Vertical turning and milling machining center:

CXK52, CXH52, CXK54 series vertical lathe and iron machining centers are high-end processing equipment, suitable for large parts with high machining accuracy requirements and long process routes. This process meets the needs of users for Louhe chemical processing. The equipment is equipped with functional components such as iron, town function, C-axis function, tool friction, tool setting instrument, tool breakage detection, etc., to meet the needs of high-end users.

Advantages of Vertical turning and milling machining center

1. Due to the simple structure of the Vertical turning and milling machining center, it is very easy to clamp the workpiece, and common fixtures can be used, such as: flat pliers, press

Plate, indexing head, rotary table and other fixtures are used to clamp the workpiece, and the clamping positioning and repeated positioning of the workpiece are very convenient and simple.

2. The structural design of the Vertical turning and milling machining center is conducive to cooling, because the coolant is sprayed from top to bottom and can be directly sprayed to the high-temperature process during machining.parts and knives.

3. The structure of Vertical turning and milling machining center is relatively simple, the running track of the tool can be observed, debugging, observation and modification of parameters are also convenient, and it is also convenient for workpiece measurement.

It is convenient to stop processing and modify immediately when problems are found.

4. Vertical turning and milling machining center is easy to remove chips when machining flat workpieces, and the generated chips are directly washed away by the sprayed coolant, which prevents the chips from scratching the surface of the workpiece during cutting.

5. Compared with the horizontal machining center, the structure of the Vertical turning and milling machining center is simpler, the floor area is smaller, and the price is also cheaper.

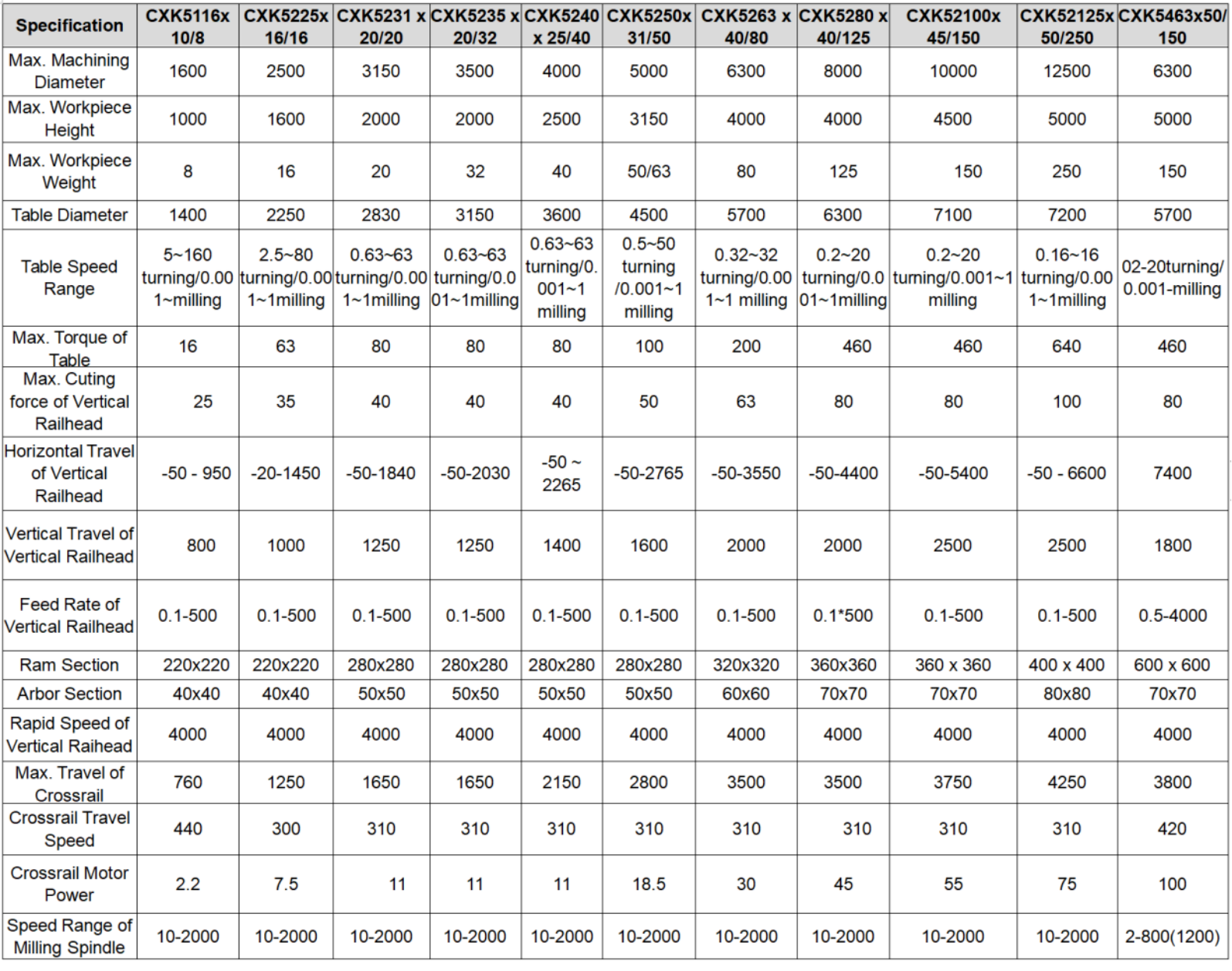

Specifications of Vertical turning and milling machining center:

Company Profile:

QIER MACHINE GROUP DALIAN WAJI CNC MACHINE Co., Ltd. is a joint-stock enterprise jointly invested by QIER Machine Group affiliated to China General Technology Group and the former DALIAN WAFANGDIAN MACHINE GROUP Co., LTD., (WAFANGDIAN HEAVY MACHINE) in 2003. The company is located in Dalian Changxing Island industrial park, the beautiful shore of Bohai Sea. Our company registered paid-in capital of 80 million, factory covers an area of 13 acres that is a modern garden factory.

Our company inherited the DALIAN MACHINE TOOL GROUP CO., LTD. WAFANGDIAN city for half a century of the machine tool manufacturing technology and talents. QIER MACHINE GROUP has abundant technical force and development manufacturing strength as the backing, a new management model and operation principle has been implemented, formed development-manufacturing-marketing rapid response system. Our company committed to build a mainly mechanical and electrical integration of high-tech enterprises.

The company take the initiative in the market and widely satisfaction the requirement raised by user, so far, have already continuously developed over 10 different kinds of CNC machines which have been widely used in the shipping industry,electricity generating and so on, in particular, the developing of vertical CNC multifunctional milling and boring machine has replaced the same type of abroad imported products in China.

The leading products include swiveling diameter ranging from 400mm to 5000mm single and double column vertical lathe both CNC and conventional type, our products have already sale over 30 different provinces and autonomous regions in civil market. marketing share of the same kind has already been over 40% for abroad. so far, we have already exported our products to 38

different countries and regions, many products have already filled the blank in China and come up to the world advanced level.

The company has already had a sales network spread all over China. We will keep our promise, good quality of products and have courage to take responsibility. Sincerely hope we can supply the best products, the best service in the most competitive price. Hoping establish multi-mode cooperation with new and old friends all around the world. Let us be the real partner.