Understand the reasons for the high price of vertical lathe

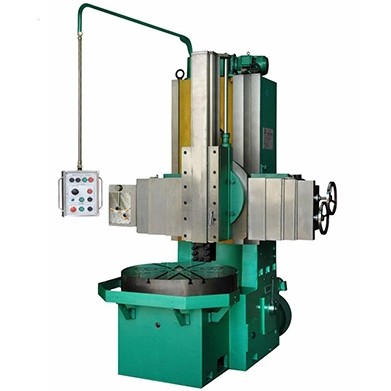

The difference between a vertical lathe and a general lathe is that its main shaft is straight, which is equivalent to putting a general lathe upright. Because the worktable is horizontal, it is suitable for processing heavy parts with large diameter and short length.

Vertical lathe can process internal and external cylinders, conical surfaces, end planes, grooves, chamfers, etc. It is convenient to clamp and calibrate workpieces.

With the rapid development of science and technology, more and more automation equipment has entered our industrial production, greatly improving the production efficiency, thus reducing the cost of products. But do you know the price of vertical lathes? Many people think that the price of automation equipment is too expensive, which makes many factories unable to afford it. They still use traditional manual methods to produce, but this production method is not only inefficient, but also does not generate high profits. Next, we will talk about the price of vertical lathes, and give a good introduction to the vertical lathes as automation equipment.

The difference between a vertical lathe and a general lathe is that its main shaft is straight, which means that it is actually equivalent to a general lathe standing upright. Because its operating platform is in a plane orientation, it can process some heavy parts with relatively large diameter but relatively short length. The vertical lathe can process the end plane cone, cylinder, chamfer and groove, It is convenient to rectify and clamp the workpiece.

Because the gravity of the workpiece and worktable is accepted by the guide rail and thrust bearing of the lathe, the spindle part of the vertical lathe will not twist, so the vertical lathe is very suitable for processing some large discs and large and short sleeve components. Therefore, the price of vertical lathe is worthy of its functions, and the cost performance ratio is very high.

The price of vertical lathe is not high. It is a large mechanical equipment, which is used to process large and heavy workpieces with large radial size and relatively small axial size and complex shape. Such as the cylindrical surface, end face, conical surface, cylindrical hole, conical hole, etc. of various discs, wheels and sleeves. Additional equipment can also be used for thread turning, spherical turning, profiling, milling and grinding. Compared with the horizontal lathe, the workpiece is clamped inside the clamp decoration of the horizontal lathe. The spindle axis of the vertical lathe is straight, and the worktable table is in the horizontal plane, so it is convenient to clamp the workpiece. This layout reduces the load on the spindle and bearing, so the vertical lathe can maintain the working accuracy for a long time.