Three major trends in the development of high-end CNC machine tools in China

CNC machine tool is the abbreviation of digital control machine tool. It is an automatic machine tool equipped with a program control system. It sends various control signals through the numerical control device to control the action of the machine tool, and automatically processes the parts according to the shape and size required by the drawing.

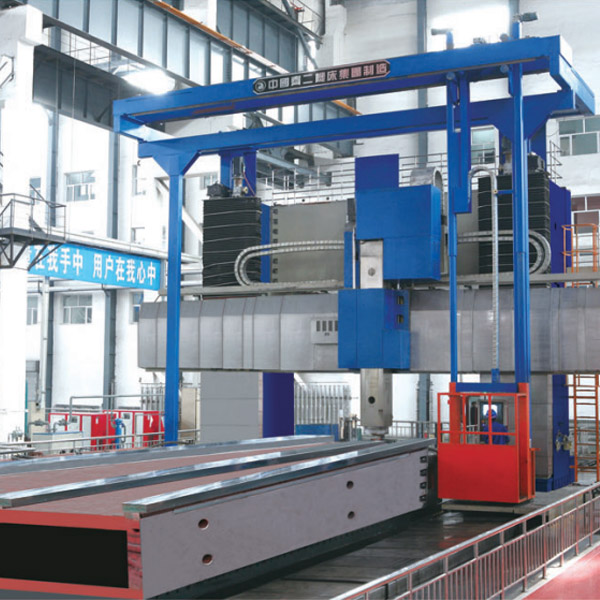

Machine tools, known as "industrial motherboards", are the foundation of the manufacturing industry and the key areas of high-end breakthroughs in the manufacturing industry, especially providing important support for high-end equipment fields such as automobile industry, aerospace, rail transit and so on. At present, the CNC machine tool industry has formed a complete industrial system, which is the second echelon in the world as a whole, providing strong support for national defense security and the construction of a powerful manufacturing country.

In recent years, thanks to the favorable national policies and the continuous pursuit of innovation by machine tool manufacturers, China's CNC machine tool industry has developed rapidly. China actively cultivates advanced manufacturing clusters and promotes the innovative development of high-end CNC machine tool industry. It is expected that the industry will usher in a period of rapid development.

Driven by the transformation and upgrading of China's domestic manufacturing industry, the rapid development of new generation of information technology and the growth of emerging industries, traditional machine tools are gradually upgraded to high-end CNC machine tools with higher technology content.

So, what is the future development trend of Chinese machine tools, especially high-end CNC machine tools?

1. In terms of market demand, the normalization of the global epidemic will accelerate the pace of import substitution. The recovery and digital reform of downstream industries such as domestic automobile and construction machinery will further stimulate market demand, and China's CNC machine tool industry will generally enter a new stage of steady growth.

2. In terms of policy supply, China's machine tool industry will focus on key areas such as aerospace equipment, automobile, electronic information equipment, and enhance its appeal to high-end and CNC fields, accelerate the innovative development and import substitution process of high-end CNC machine tools, and the domestic CNC machine tool industry will usher in a good opportunity for development.

3. In terms of competition, China's CNC machine tool industry can meet the current demand of the low-end CNC machine tool market, and it mostly adopts the outsourcing core parts+independent production and processing mode. The R&D and design capacity in the high-end field is still seriously insufficient, 80% of CNC systems are still highly dependent on imports, the independent production capacity of core parts is low, and the overall domestic penetration rate is only 6%. The pattern of foreign enterprises leading the domestic high-end machine tool market will be difficult to change significantly in the short and medium term.