Do you really understand CNC machine tools

CNC lathe is a widely used milling machine, which can grind and polish plane, groove, tooth-shaped parts and various curved surfaces. In addition, it can also be used as the surface layer of rotary body for drilling and crushing operations. When the CNC lathe is running, the casting is installed on the worktable or indexing plate and other accessories, and the turning tool rotates to drive the movement, supplemented by the feed movement of the worktable or boring tool, to obtain the required polished surface. In view of the continuous drilling with multiple cutters, the production efficiency of CNC lathe is high.

A milling machine for cutting, grinding and polishing castings with a boring cutter. In addition to cutting planes, grooves, gear teeth, threads and spline shafts, CNC lathes can also polish and polish complex summaries at a higher speed than drilling machines, and have been used in mechanical equipment manufacturing and repair organizations.

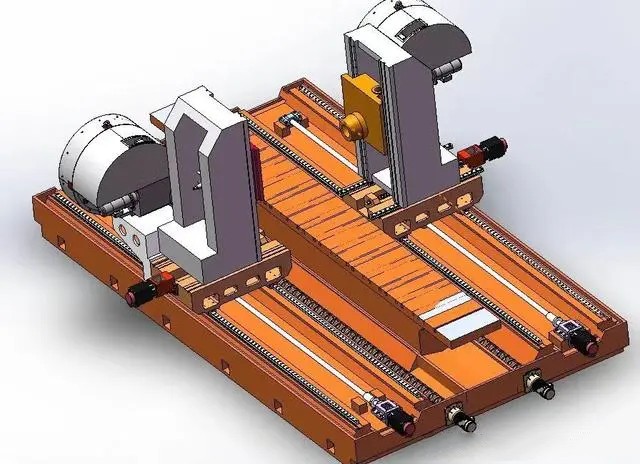

CNC lathe is suitable for cutting plane, slope, groove, etc. It is equipped with various bar boring cutters, circular boring cutters and viewpoint boring cutters. If the universal milling head, circular worktable, indexing plate and other drilling machine accessories are selected, the polishing range of CNC lathe can be added. CNC lathe has arbitrary rigidity and power, strong processing ability, and can complete high-speed and heavy-load drilling and gear processing. It is suitable for grinding and polishing abrasives, special steel, mining machinery and equipment, production equipment and other large and medium-sized heavy precision processing. The table of the vertical milling machine can rotate 45 degrees to the left and right respectively. When the operating table rotates with a certain inclination, when selecting the parts of the indexing plate, it can also grind various spiral surfaces. The three-way feed lead screw of boring machine is trapezoidal lead screw or ball screw.