What type of motor is used for CNC machine tools?

The computer numerical control (CNC) machine tool is an extremely complex mechanical component, which has many moving parts. These CNC machine tools' motors are responsible for providing power for the movement of these machine tools and providing high torque at a fairly constant speed. These motors also need to run smoothly for a long time, which may be a challenge to achieve with so many different moving parts. The motors used in CNC machine tools have many sizes and types, and each motor has its own unique characteristics. When CNC machine tools move objects from one point to another by using various tools, there are universal motors using permanent magnetic fields. These tools can take away a small amount of materials at a time. This means that the motor of CNC machine tool needs to be able to generate enough force to cut all types of materials without overheating.

How does a CNC motor work?

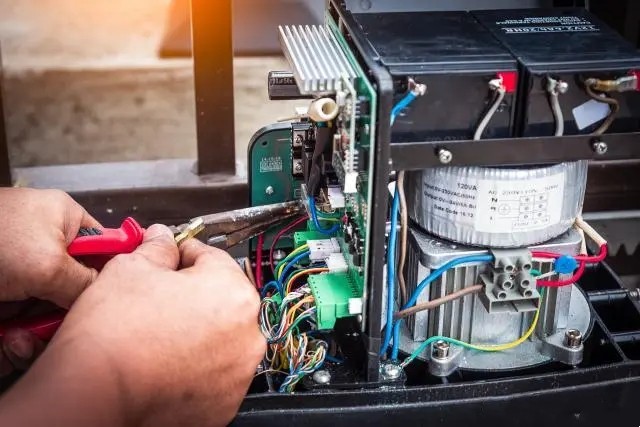

The motor of CNC machine tool generates motion by converting electrical energy into mechanical energy. In this process, the current flows through the wire wound on the armature. When the current passes through the wire, a magnetic field will be generated to pull the soft iron core, which will cause the motor shaft to rotate inside the machine, thus causing the machine parts to move.

The motor of numerical control machine tool generates motion by converting electrical energy into mechanical energy. The numerical control machine tool is controlled by a computer, and the computer sends instructions to the machine tool controller. There are four types of motors for CNC machine tools, including stepping motor, servo motor, DC gear motor and AC gear motor. Each motor has its own advantages and disadvantages, allowing the selection of appropriate motors according to specific applications.

What are CNC motors used for?

Numerically controlled machine tools motors are used for a variety of different machines that rely on automated processes, so they are often used in manufacturing. Stepping motors are usually used for 3D printers, while servo motors are used for mechanical arms and machine tools. DC gear motor is used for the spindle of CNC machine tools, while AC gear motor is used to drive the spindle of CNC machine tools. Stepping motors are commonly used in 3D printers, laser machines, and other automated processes that rely on precise motion. The stepper motor moves in small, equal increments to ensure that all movements are accurate. These motors are common in CNC machine tools and allow precise movement. Servo motors are usually used for mechanical arms and machine tools, which can move quickly and accurately. These motors can move from one end of the range of motion to the other in a fraction of a second. These motors are used in CNC machine tools and can respond quickly to computer control. DC gear motors are usually used for NC machine tool spindles. They can generate high torque while maintaining a constant speed. These motors can generate a lot of force while maintaining a fairly constant speed, which is very important for NC machine tools.