Three Methods of Machining Thread with CNC Machining Center

There are three ways to use NC to process threads: thread milling, tap processing and thread picking processing.

1、 Thread milling method

Thread milling refers to the use of thread milling tools for processing large hole threads, as well as the processing of threaded holes that are difficult to machine materials. It has the following characteristics:

(1) The cutting tool is generally made of cemented carbide, with high speed, high precision of milling thread and high processing efficiency;

(2) With the same pitch, a tool can be used for both left-hand and right-hand threads, reducing the cost of the tool;

(3) The thread milling method is especially suitable for the thread processing of stainless steel, copper and other difficult materials, which is easy to remove chips and cool, and can ensure the quality and safety of processing;

(4) It is convenient to process blind holes with short thread bottom holes or holes without undercut without tool front guide.

2、 Tap machining method of CNC machining center

It is applicable to threaded holes with small diameter or with low requirements for hole position accuracy. Generally, the diameter of the threaded bottom hole drill is close to the upper limit of the diameter tolerance of the threaded bottom hole, which can reduce the machining allowance of the tap, reduce the load of the tap, and improve the service life of the tap.

We should select the appropriate tap according to the materials processed. The tap is relative to the milling cutter and the boring cutter;

Very sensitive to processed materials; The taps are divided into through hole taps and blind hole taps. The front guide of through hole taps is long, which is the front chip. When machining blind holes, the processing depth of threads cannot be guaranteed, while the front guide of blind holes is short, which is the back chip. Therefore, pay attention to the difference between the two; When using a flexible tapping chuck, it should be noted that the diameter of the tap shank and the width of the square should be the same as the tapping chuck; The diameter of the shank of the tap for rigid tapping shall be the same as that of the spring jacket.

The programming of tap processing method is relatively simple. It is a fixed mode, so it is OK to add parameter values. It should be noted that different numerical control systems have different formats of subprograms, so the representative meanings of parameter values are different.

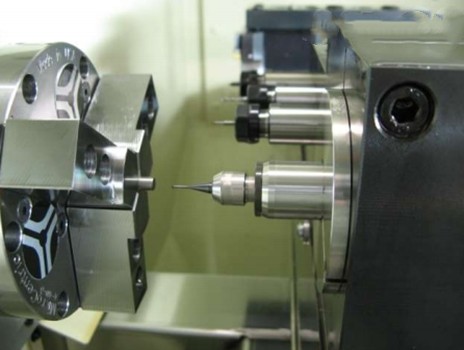

3、 Buckling processing method

The thread picking processing method is applicable to the processing of large threaded holes on box type parts, or it is used when there is no tap and thread milling cutter. The thread turning cutter is installed on the boring cutter bar to bore the threads. There are several precautions for implementing the thread picking processing method:

(1) There shall be a delay time for starting the spindle to ensure that the spindle reaches the rated speed;

(2) The grinding of the hand ground thread cutter cannot be symmetrical, and the reverse tool retraction cannot be used. The spindle shall be used to orient the cutter to move radially, and then the tool retraction shall be carried out;

(3) The cutter bar must be accurate and consistent with the position of the cutter groove, otherwise, multiple cutter bars cannot be used for processing, resulting in disorderly buckling;

(4) When picking the buckle, pay attention not to pick it up with one knife, even if it is very thin, otherwise it will cause tooth loss and poor surface roughness, so you should pick it up with multiple knives;

(5) The thread picking method is only applicable to single piece, small batch, special pitch thread and no corresponding cutter, and the processing efficiency is low.