How to determine the cutting capacity of double column vertical lathe?

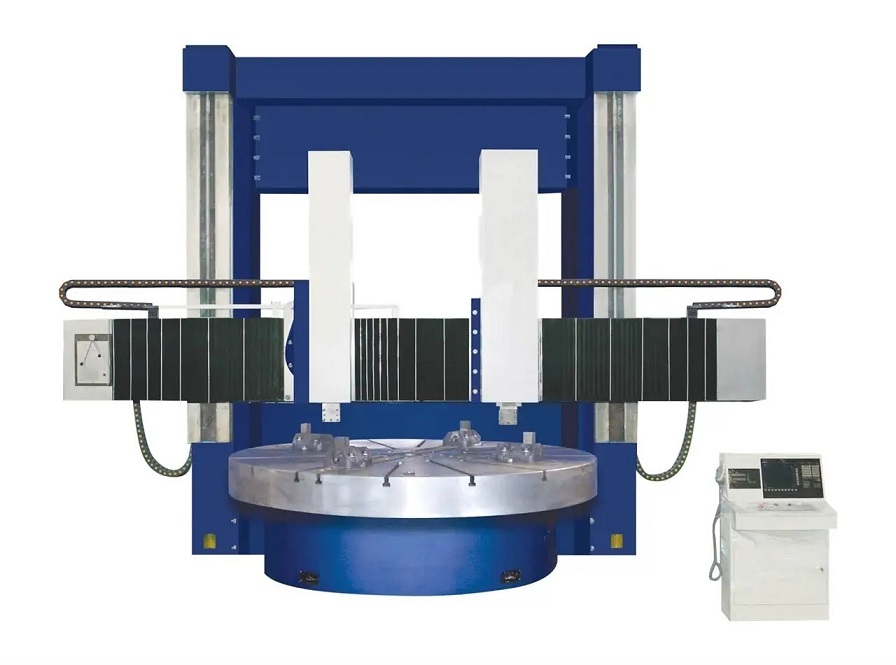

The single column vertical lathe and the double column vertical lathe belong to one of the lathes, that is, the universal ordinary lathe in the vertical lathe series, which is suitable for processing the excircle, cone surface, drilling, reaming, and boring of a variety of small and medium-sized annular parts, shells, flanges, and other parts. So, do you know which cutting diameter is larger? What are the methods for determining the cutting capacity of double column vertical lathe?

1. Comparison of cutting diameters

If the cutting diameter of the single column vertical lathe is compared with that of the double column vertical lathe, then from a professional perspective, the double column vertical lathe is larger, because it can reach more than two meters, while the single column vertical lathe is less than two meters.

2. The Method of Determining the Cutting Capacity of Double column Vertical Lathe

In the double column vertical lathe, the cutting capacity is generally related to the cutting force of the tool holder and the power of the main motor. However, it should be noted that sometimes it depends on the bearing capacity of equipment and tools. Because, it is also related to these two. However, the first two are the main factors that must be taken into account and cannot be ignored. The last two are based on the actual situation to decide whether to take into account.

3. Concrete Measures for Prolonging the Service Life of Double column Vertical Lathe

First of all, the equipment should be used correctly and normatively, and its daily and regular maintenance should be done well. In addition, in terms of equipment manufacturing, advanced technology and high-quality materials are used to ensure product quality and use effect. The above points can ensure the service life of the equipment and can be appropriately extended.